What is CFRP? Detailed Explanation about Characteristics, Applications, and How to Select a Molding Method

CFRP is a type of composite material that combines two or more materials, and when carbon fiber is added as a reinforcing material, it is called CFRP (Carbon Fiber Reinforced Plastics = "plastics reinforced/strengthen with carbon fiber"). In addition to characteristics of high rigidity and strength, carbon fiber also has other characteristics of electrical conductivity/heat resistance/low thermal expansion/self-lubrication/X-ray transparency. By taking advantage of these characteristics, carbon fiber can be expected to achieve lighter weight, larger size, smaller size, or more energy-efficient products, and is used in a wide range of applications such as aerospace, automobiles/motorcycles, sports, medicine, and construction.

Contents

- Characteristics of CFRP

- Applications and Reasons for Use of CFRP

Aviation/Space/UAV (Unmanned Aerial Vehicles, Drones)/Air Mobility

Automobile/Industrial Equipment

Civilian Daily Necessities/Leisure/Sports - Characteristics required for CFRP other than lightness and strength

- Differences between CFRP and Metal Materials

- The flow — initial concept → design/analysis → commercialization — is most important in CFRP product development.

- How to select a molding method for CFRP

Comparison of Molding Methods

Standard for choosing Molding Methods - The intermediate base material used during CFRP molding

Carbon Fiber and Composite Materials (from intermediate base materials to molding methods)

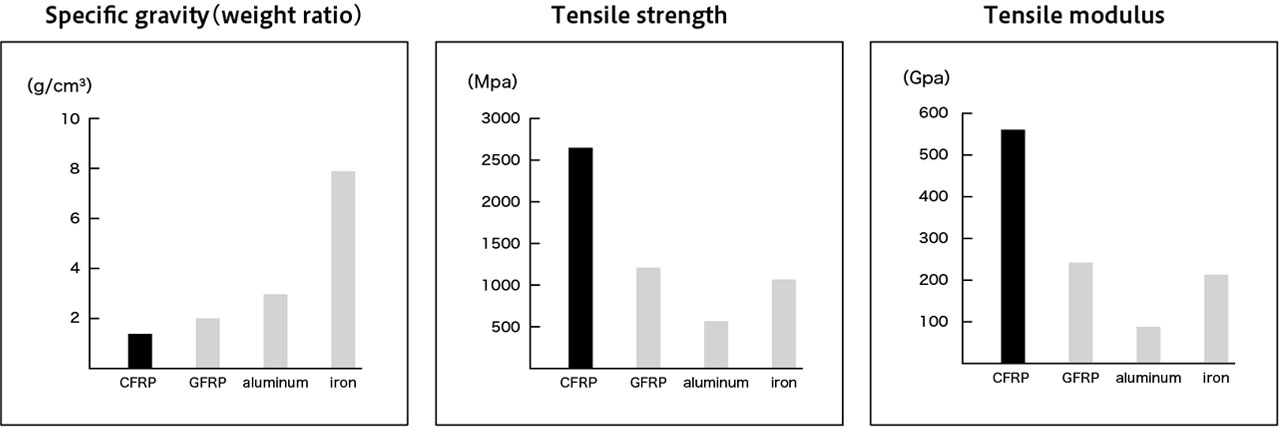

Characteristics of CFRP

The characteristics of CFRP are that it is light/strong/noncorrosive. In addition, it has various characteristics of high fatigue strength, excellent chemical resistance, and stability in normal thermal environments, and is used in sports/leisure applications, automobiles/motorcycles, civil engineering and construction, industrial equipment, etc. It is a highly reliable material that has been used for many years under severe conditions such as in the aerospace field and in racing cars.

However, as for parts, that will be used outdoors for long periods of time, painting or plating is required to prevent deterioration of the quality of the base material, and the base material, fiber type, surface treatment, needs to be selected according to the usage environment.

What makes CFRP unique is that the material is anisotropic. Metals and plastics are isotropic materials, but CFRP is a combination of fibers and resin, which have different properties, and its rigidity and strength can be changed by modifying the fiber orientation or material type. For example, it is possible too, to realize something that is lighter than aluminum and, in some directions, has greater rigidity than iron. CFRP allows for designs that are unique to it, such as the realization of part shapes that cannot be made with metal and the integration of multiple metal parts into a single shape.

“The characteristics of CFRP are that it is light/strong/noncorrosive”

Applications and Reasons for Use of CFRP

CFRP was originally adopted for sports/leisure goods, such as golf shafts, tennis rackets, and fishing rods, but because of its many excellent characteristics as a material, it is now used in a wide range of fields, including aerospace, automobiles/motorcycles, industrial equipment, medical care/nursing care/welfare, construction civil engineering/interior, and attractions. In addition, recently it has been actively adopted in cutting-edge technology fields, such as realization of large/small UAV (unmanned aerial vehicles, drones) and air mobility (flying cars, hoverbikes) which require lightweight.

Aviation/Space/UAV (Unmanned Aerial Vehicles, Drones)/Air Mobility

| Applications | Usage Example | Reasons for Adoption |

|---|---|---|

| Aircraft | Primary Structure: Wings, Tail, Fuselage, Floor Beams Secondary Structure: Ailerons, Rudders, Elevators, Fairings Interior Materials: Seats, Floor Panels, Lavatories |

Lightweight, Fatigue Resistance, Heat Resistance, Flame Retardancy LCA (Life Cycle Assessment) |

| Rocket | Satellite Fairing, Interstage Section, Motor Case, Nozzle Throat | Lightweight, Fatigue Resistance, Heat Resistance, Flame Retardancy LCA (Life Cycle Assessment) |

| Artificial Satellite | Antennas, Solar Panels, Tube Truss Structures | Lightweight, Low Thermal Expansion Ratio, High Thermal Conductivity |

| Radio Telescope | Antennas, Support Pillars | Lightweight, Rigidity, Low Thermal Expansion Ratio |

Automobile/Industrial Equipment

| Automobile | Usage Example | Reasons for Adoption |

|---|---|---|

| Automobile | Structure: Monocoque Body, Crash Box Structure Exterior Panels: Roof, Hood, Fenders, Spoilers Interior: Seat Frames, Instrument Panels Power System: Wheels, Springs, Leaf Springs, Dampers, Propeller Shafts, Transaxles, Battery Cases |

Lightweight, Fatigue Resistance, Vibration Damping, Design Impact Energy Absorption |

| Motorcycle | Structure: Body Frame, Swingarm Exterior Panels: Cowl, Gear Cover, Muffler Cover Power System: Wheels |

Lightweight, Heat Resistance |

| Railway | Vehicle Body, Vehicle Bogie, Seat, Waterstop Plate | Lightweight, Rigidity, Corrosion Resistance |

| Machinery Parts | Transport Robots, Leaf Springs, Robot Arms, Assist Suits | Lightweight, Rigidity, Vibration Damping |

| High Speed Rotating Body | Centrifuge Rotors, Uranium Enrichment Cylinders, Flywheels Industrial Rotors, Shafts, Rayon Pots |

Lightweight, Fatigue Resistance, Rigidity, Corrosion Resistance |

| Electrical Parts | Parabolic Antenna | Lightweight, Fatigue Resistance |

| Pressure Vessels | CNG Tanks, Hydrogen Tanks, Air Breathing Cylinders for Firefighting | Lightweight, High Strength, Fatigue Resistance |

| Medical Equipment | Top Plate, Cassette, X-ray Grid, Retractor | Lightweight, X-ray Transparency |

| Welfare/Nursing Care | Wheelchairs, Portable Wheelchair Ramps, Prosthetic Feet, Knee Joints, Walking Sticks, Assist Suits | Lightweight, Fatigue Resistance |

| Civil Engineering and Construction | Concrete Reinforcement, Cables, Rods | Lightweight, Corrosion Resistance, Impact Energy Absorption |

Civilian Daily Necessities/Leisure/Sports

| Applications | Usage Example | Reasons for Adoption |

|---|---|---|

| Electric Appliances | PC Cases, Housings, Audio Speakers, Smartphone Covers | Lightweight, Rigidity, Electromagnetic Shielding Fatigue Resistance, Vibration Damping |

| Daily Life Items | Eyeglass/Sunglass Frames, Helmets, Bags, Furniture | Lightweight, Rigidity |

| Fishing Equipment | Fishing Rods, Reels | Lightweight, Rigidity |

| Golf | Shaft, Club Head, Face Plate | Lightweight, Rigidity |

| Bicycle | Frame, Wheel, Handle, Crank | Lightweight, Rigidity, Vibration Damping, Fatigue Resistance |

| Ocean | Yachts, Cruisers, Competition Boats, Masts | Lightweight, Rigidity, Fatigue Resistance, Corrosion Resistance |

| Others Sports |

Canoes, Boards for Skis/Snowboards, Ski Poles, Kendo Shinai Japanese Bows, Western Bows, Radio-controlled Cars, Billiards |

Lightweight, Rigidity, Vibration Damping, Fatigue Resistance |

| Parasports | Wheelchairs for Competitions, Prosthetic Feet for Athletics | Lightweight, Rigidity, Fatigue Resistance |

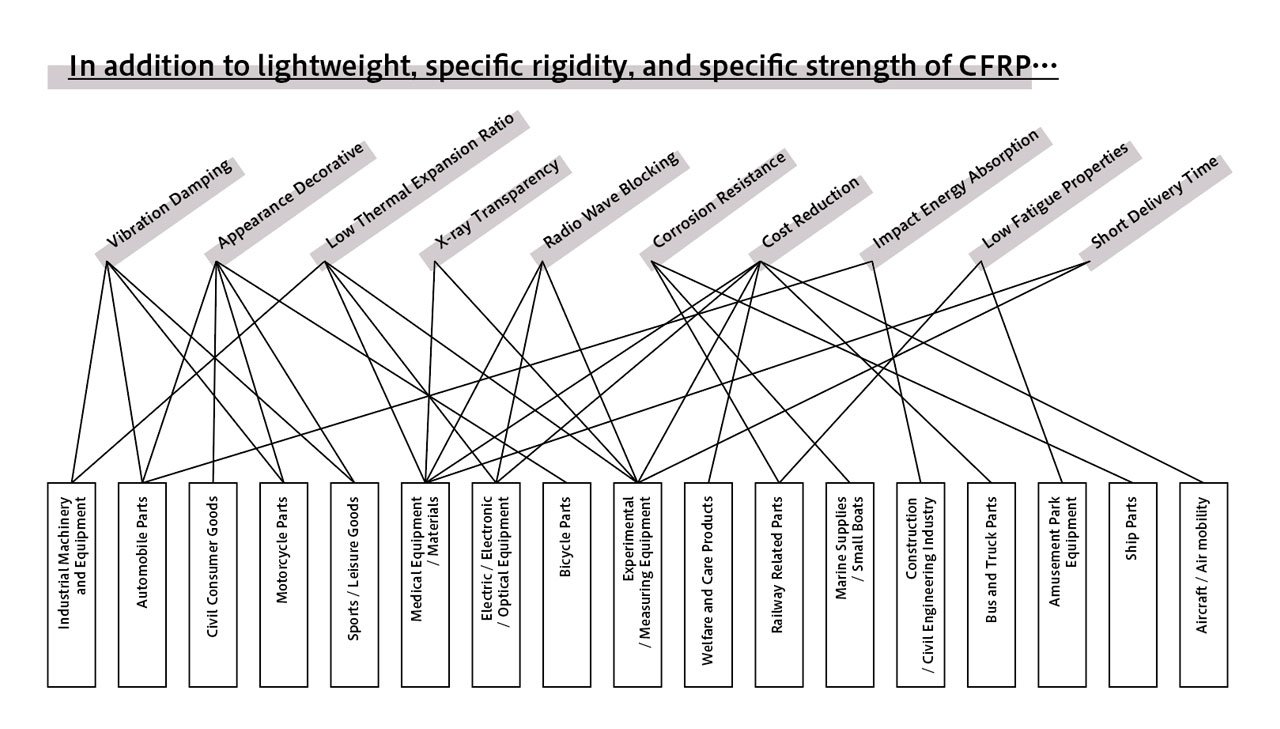

Characteristics required for CFRP other than lightness and strength

We have explained that the characteristics of CFRP are that it is light and strong, but in actual product development, CFRP is not adopted solely for these reasons. CFRP has a variety of characteristics required for each application. For example, CFRP has better vibration damping than metals. This is because the base material is a resin. The vibration damping of CFRP can be changed by modifying the resin material, too. By taking advantage of this property, products with superior properties to metals can be made in applications such as automobiles and motorcycles that require vibration damping. If you play golf, you will understand this more easily if we say that a carbon shaft has different properties than a metal shaft.

In addition, the high X-ray transparency compared to metal materials is another major feature of CFRP. This property is utilized in medical and measuring equipment applications. For example, in X-ray imaging equipment, the high X-ray transparency of CFRP can be used to reduce the amount of radiation received during imaging, thereby lowering exposure to radiation.

In addition, by taking advantage of many other characteristics not found in resin or metal materials, CFRP products that are not just light and strong are being developed.

“There are many products that combine features unique to CFRP in addition to lightweight.”

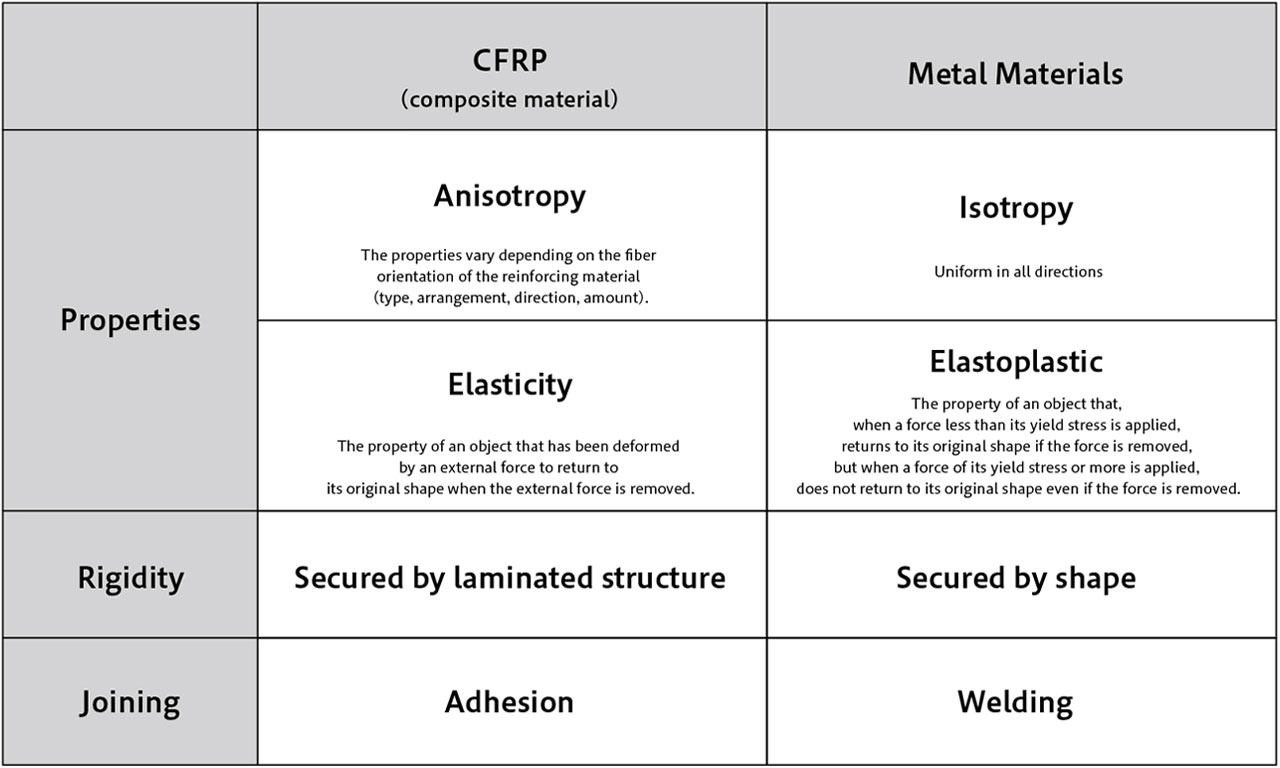

Differences between CFRP and Metal Materials

As explained above, the properties and rigidity of CFRP vary greatly depending on the material and molding method used. In addition, bonding and adhesion are used to join parts together, and it is difficult to use welding, which is commonly used with metal materials. In other words, because of the material characteristics of CFRP, there are many design items that differ from metals, such as anisotropy, lamination, and adhesion, so the way we think about design requires a major change.

In particular, composite materials are a combination of a base material and reinforcing fibers, so their physical properties can change if the shape or molding method is changed. In other words, the molding method requires to be considered along with the structure. When advancing product design, the manufacturing method will be considered in parallel at the same time and incorporated into the design.

“Composite materials have different design items from metal materials and, design on both material and structure is required.”

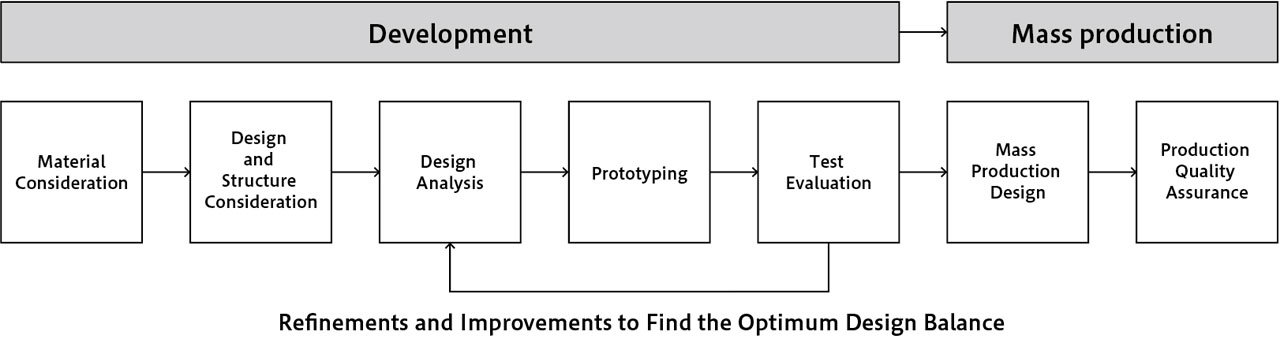

The flow — initial concept → design/analysis → commercialization—is most important in CFRP product development.

The development of CFRP products is carried out as follows.

With CFRP, in addition to pursuing shape and materials used in the same way as with metal materials, in order to pursue design items specific to composite materials, such as molding methods and laminate design, not only analysis but also trial and error of prototyping and test evaluation is conducted to pursue the optimal balance in the design. In particular, when moving from development to mass production, product design and manufacturing methods must be maintained at an extremely high level of perfection, but it is also important to efficiently carry out the processes of design, analysis, prototyping, testing, and evaluation in order to find the optimal design balance that satisfies performance, quality, and cost requirements at high level.

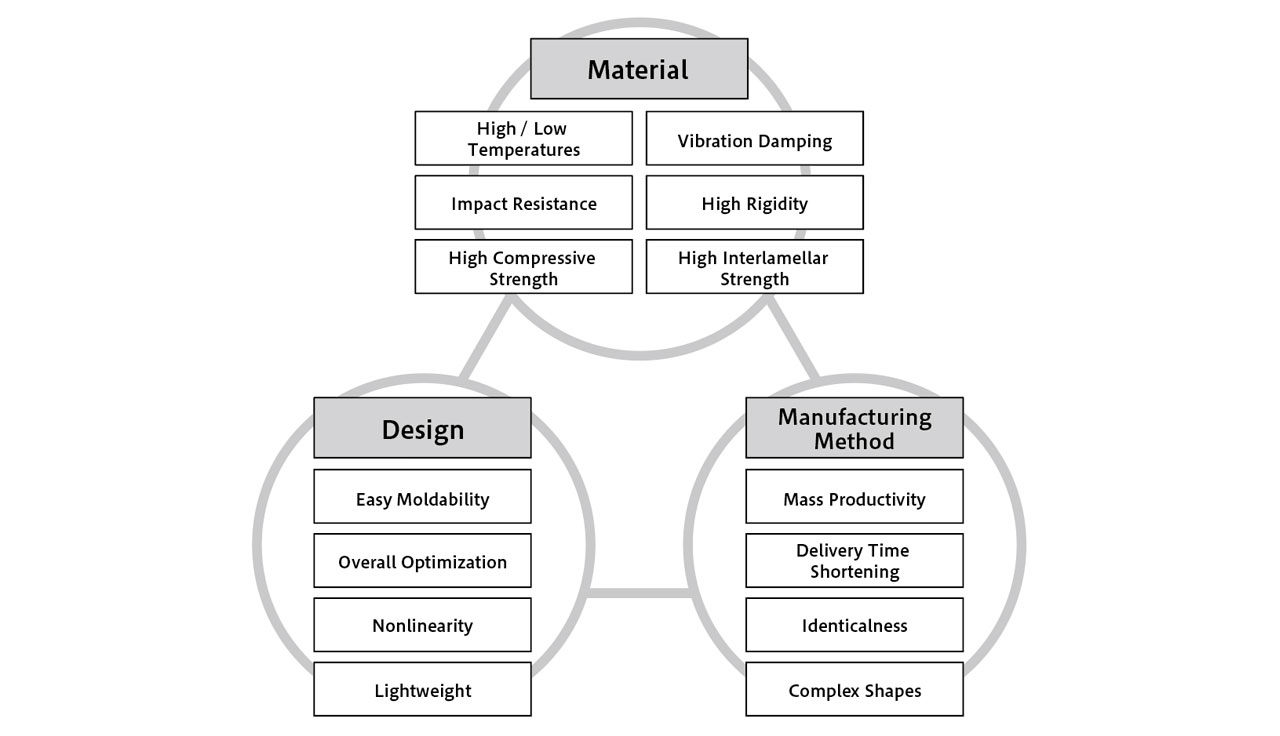

The key to produce high-performance composite products that maximize the characteristics of CFRP is the concept that comes before development starts. As shown in the diagram below, there are many issues in the three major design elements of CFRP: materials/manufacturing methods/ design, that should be considered in the design aspect for each of them. However, by clarifying the product concept that incorporates the unique features of composite materials, also taking into account key points in the development and production stages, we aim to improve the performance and quality of the final product.

“The most important thing is to find the “optimum design balance” of Materials, Design and Manufacturing Methods using appropriate evaluation methods”

How to select a molding method for CFRP

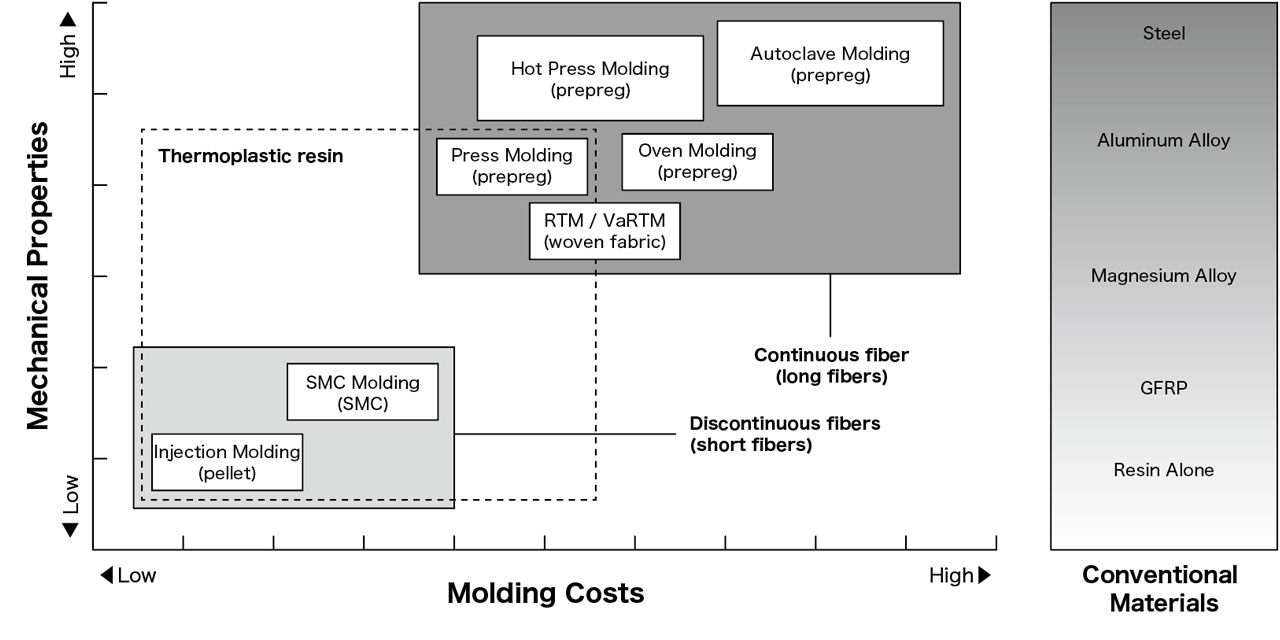

CFRP molding methods have evolved according to required characteristics, costs, and production volume, and carbon fiber base materials and resins have been developed according to the molding methods. It is necessary to select the most suitable molding method among autoclave molding, press molding, filament winding molding, sheet winding molding, pultrusion molding, and RTM molding, which matches the requirements for shape, quality, quantity, etc.

Each molding method has its own characteristics. For example, products molded with use of autoclave molding are perceived as expensive when compared on a part-by-part basis, but in the case of small-lot production of a wide variety of products, there may be cost benefits. Since the carbon fiber can be molded while maintaining its fiber length, high mechanical properties are obtained and complex three-dimensional shapes can also be molded. This makes it possible to reduce assembly labor by integrating parts, so costs need to be compared based on total cost rather than on a part-by-part basis.

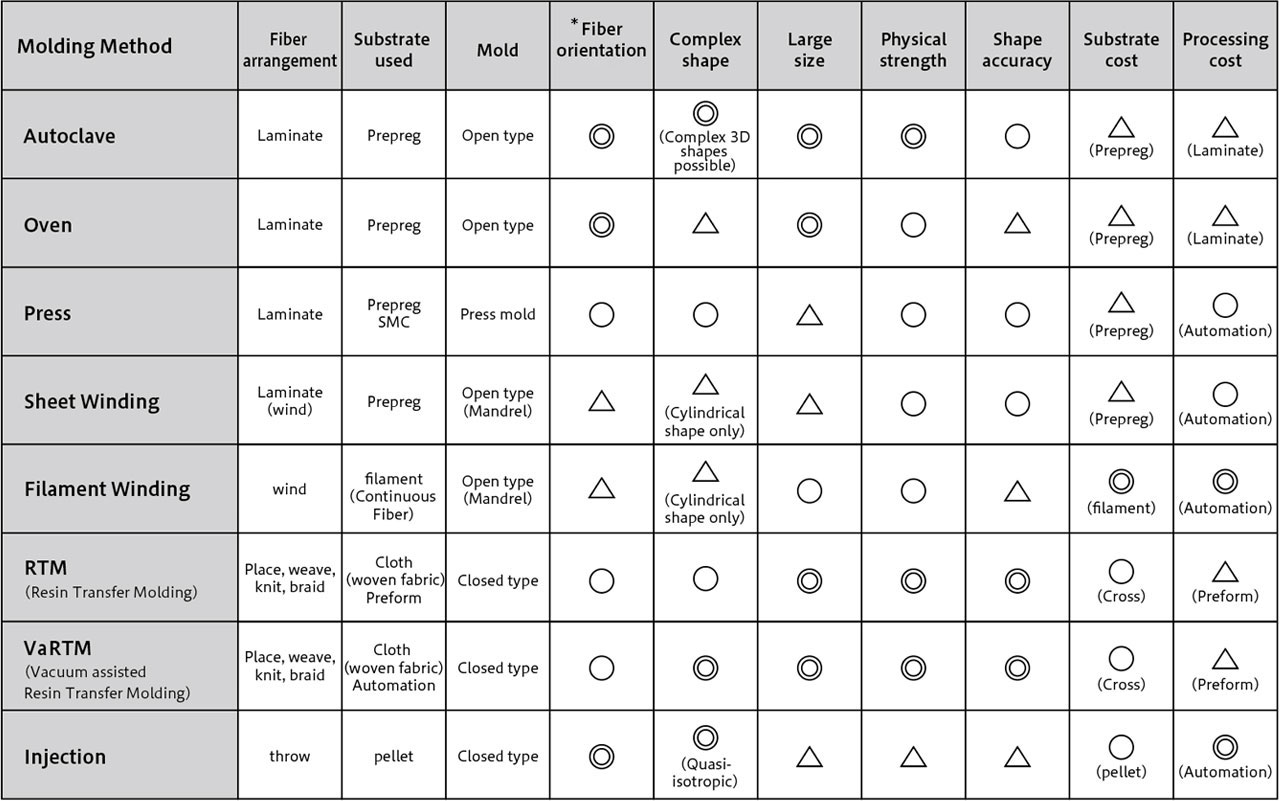

Comparison of Molding Methods

Standard for choosing Molding Methods

*Fiber orientation is a phenomenon in which resin shrinkage becomes uneven due to differences in the direction in which the fibers are arranged. In the case of CFRP products that use carbon fiber as a reinforcing material to give them high strength, this is one of the causes of warping deformation that must be taken into consideration.

“Select the optimal molding method that matches the requirements such as shape, quality, and quantity.”

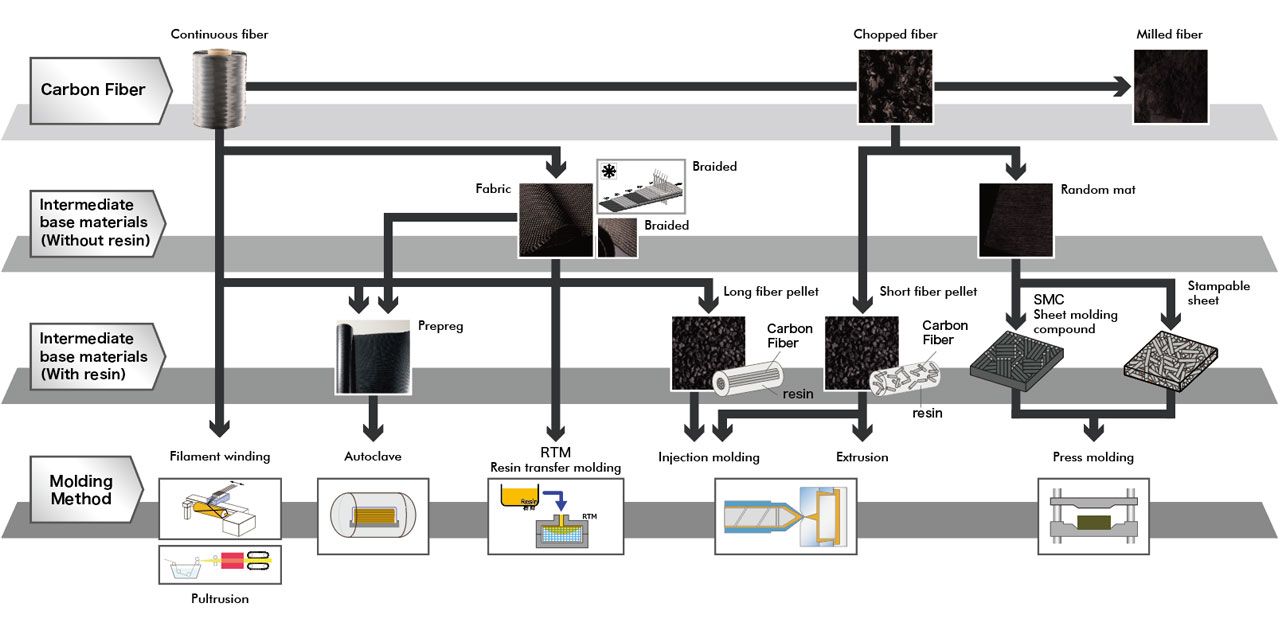

About the intermediate base material used during CFRP molding

There are two types of intermediate base materials: those that are pre-impregnated with resin (prepreg, pellets, SMC), and those to which resin is added during molding (chopped, woven). Intermediate base materials are made according to the molding method, and are closely related to the manufacturing method.

Carbon Fiber and Composite Materials (from intermediate base materials to molding methods)

“As for CFRP products with use of carbon fiber, base material and manufacturing method are closely related.”