Features

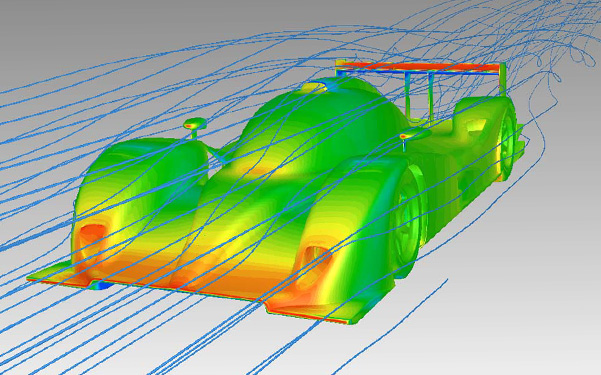

Today’s racing cars such as F1 cars and Le Mans cars are the result of carbon fiber composites (CFRP) technology. Our well-honed machines designed for ultimate weight saving, evolved in the cutthroat field of car racing, are also an assembly of parts of rational and functional beauty without a trace of waste. Toray Carbon Magic (TCM) uses its lightweight design technology and CFRP molding processing technology cultivated over many years of racing car development to dramatically improve the performance of many different kinds of parts and structures. From precision and complex parts to large structures, from design and analysis to prototyping and mass production, please feel free to contact us with any enquiries you may have.

Major features and functions of Toray Carbon Magic

| 01 | A complex of technologies steeped in engineering expertise | |

|---|---|---|

|

Far from relying solely on our composite material technology, we take on monozukuri (manufacturing) with a complex of technologies, making full use of our expertise in machinery, fluid, control, electrical, electronics, and other fields. |

||

| 02 | All processes implementable in-house | |

|

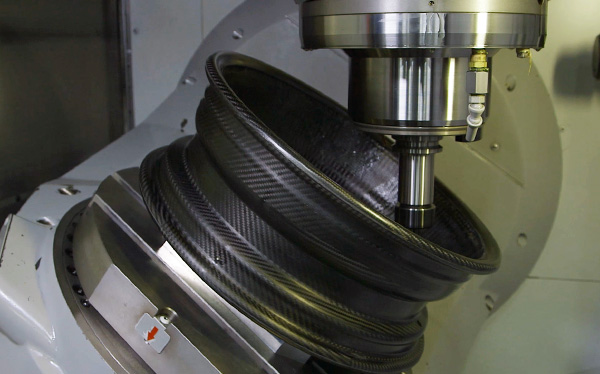

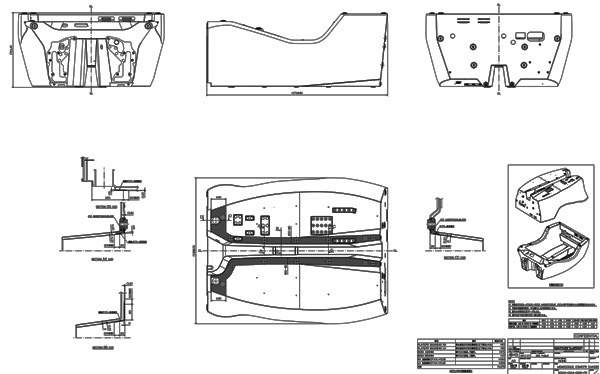

With our R&D and manufacturing facilities and staff capable of responding quickly to broad-ranging development requirements, we can implement in-house an array of processes from planning and design of carbon composite products to prototyping, evaluation, and completion. Production systemMore |

||

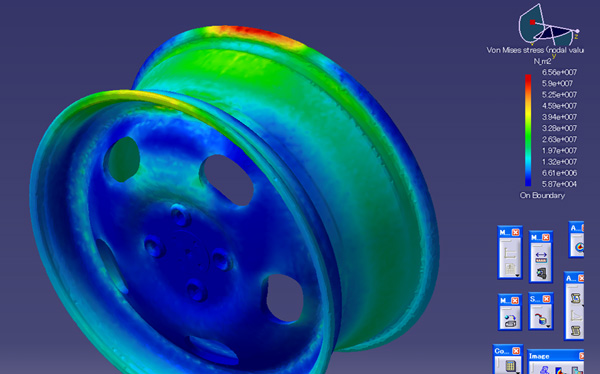

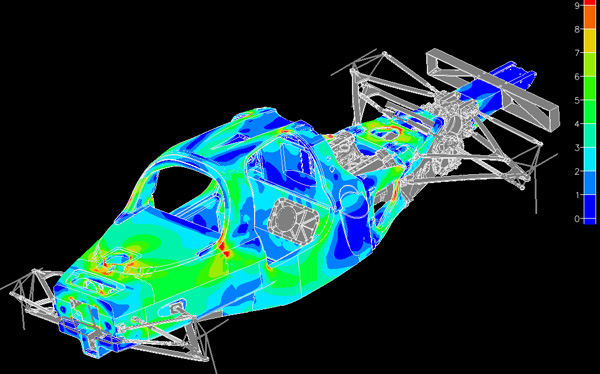

| 03 | Validity simulation of carbon composites application (structural analysis) | |

|

We evaluate the validity of applying carbon composites based on a full understanding of the technical requirements and background of the products to be developed. Through preliminary simulation (structural analysis), we determine the effects of the application of carbon composites. Analysis and design processMore |

||

| 04 | Quick development | |

|

Quick development is a special strength of TCM that makes full use of the nimbleness and the design and prototype processes we have evolved through our experience in racing car development. |

||

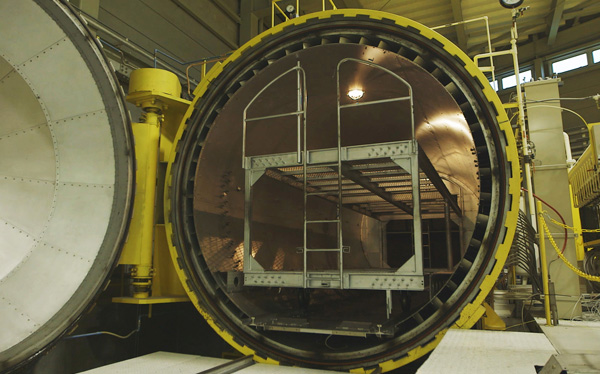

| 05 | Autoclave molding, the most realistic way for product realization | |

|

Autoclave molding, a TCM specialty, is a manufacturing method that, while best bringing out the performance and reliability of carbon composites, is regarded as costly in terms of required facilities and labor. However, through the use of proprietary design know-how, improved processing methods, and our utilization of CMTH, we have been able to lower the cost of this manufacturing method to make it the most realistic method for realizing our products. Molding equipmentMore |

||

| 06 | Pursuit of the actual commercialization of products | |

|

Pursuit of the actual commercialization of products We aim to achieve the commercialization of products, including ones for which it is not possible to achieve a reasonable cost-performance balance simply through the use of different materials and weight reduction, through our know-how and development capabilities making full use of the unique characteristics of carbon composites in an integrated manner. Various productsMore |

||

| 07 | Judicious selection of materials such as metals and resins for optimum results for the intended application | |

|

Products that can successfully be made only of carbon composites are extremely rare. At TCM, we efficiently achieve the functional, performance, and cost requirements of each product through judicious selection of the best materials, such as metals and resins. This approach and know-how come from racing car technology, which prioritizes function and performance above all else. |

||

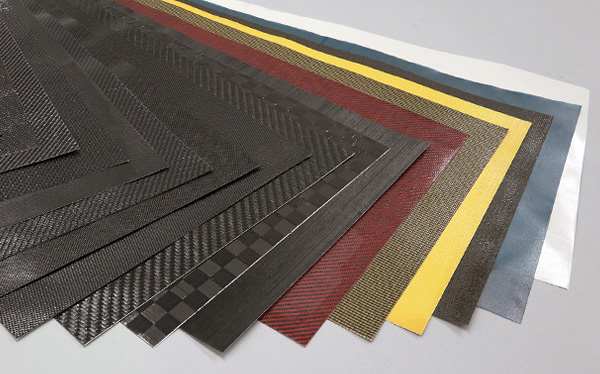

| 08 | Realization of appropriately laminated structure | |

|

By closely collaborating with material manufacturers, we are able to procure excellent Japanese-made carbon fiber materials quickly and at reasonable cost and realize appropriate laminated structures. |

||

| 09 | Use of research institutions | |

|

For issues related to composites, we also use research institutions such as affiliated manufacturers, material manufacturers, universities and so on, in addition to the Toray technical team, to quickly investigate causes and take appropriate measures. |

||

| 10 | We apply strict quality control and assurance systems to all products. | |

|

In addition to ISO 9001 certification, we acquired JIS Q 9100 certification. Furthermore, we obtained Nadcap, which is the special process certification program for composites in the international aerospace industry, and Boeing’s composite material molding process certification and supplier certification. We established a complete traceability system that we strictly apply to all our products. |

||

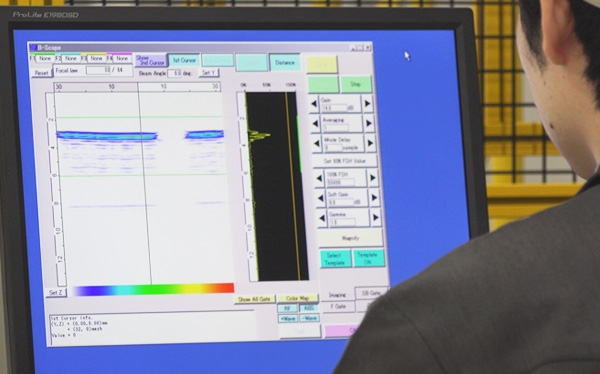

| 11 | Establishment of a superlative standard unique to carbon composites | |

|

Our inspection system uses quantitative inspection through the latest measuring technology (CMM, laser, FFT, ultrasonic flaw detection, X-ray, and so on), ensuring a superlative standard unique to carbon composites. Inspection EquipmentMore |

||

| 12 | Realization of stable and low-cost mass production | |

|

Mass production requires a system and an orientation that differ from trial production. The products we develop, after being prototyped at TCM, are batched to CMTH in Thailand, maintaining the same construction methods and procedure as those of TCM to achieve stable mass production at low cost. Mass Production Factory in ThailandMore |

||