- HOME(日本語)

- HOME

- Competition & Challenge Project

- Concept EV "ItoP"

Concept EV "ItoP"

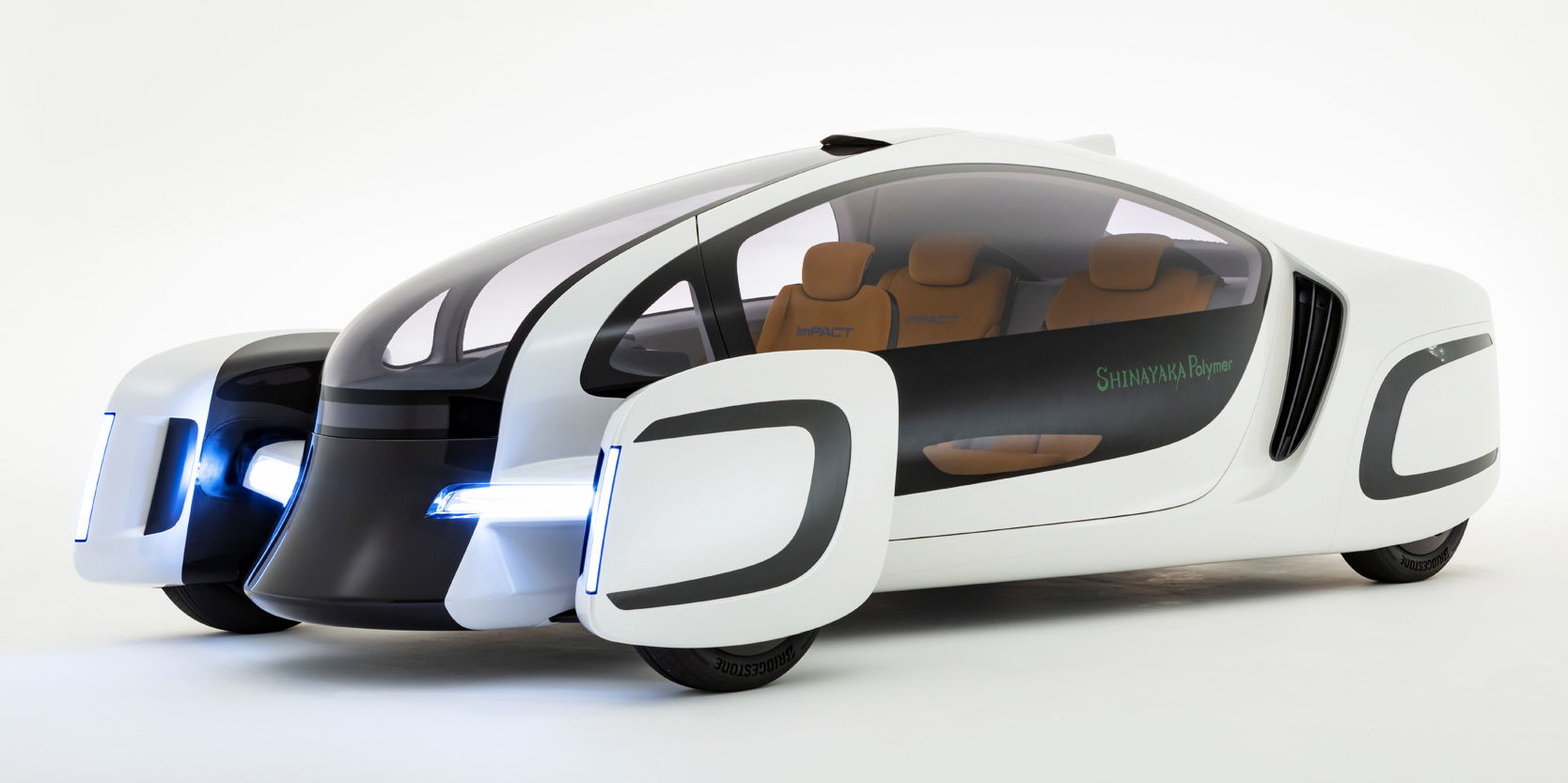

Development of an innovative concept car utilizing our new material "Shinayaka polymer"

This is the result of efforts made by Toray Carbon Magic Co., Ltd. (hereinafter referred to as Toray Carbon Magic) as part of the program "Realizing Ultra-thin and Flexible Tough 'Shinayaka polymer’” (hereinafter referred to as "the Program“, led by Program Manager Kohzo Ito), one of the projects of the Impulsing Paradigm Change through Disruptive Technologies (ImPACT) Program led by the Cabinet Office Council for Science, Technology and Innovation.

Transport equipment such as cars are in the process of evolving through motorization and improvement in safety, resulting in increased weight, and now the weight reduction of component parts and mainly the body has become an urgent and critical proposition.

With this research and development project, we attempted to ascertain the characteristics of the "Shinayaka polymer" material group created through the Program, search for effective parts of automobiles for application, and consider specific application methods while also creating a vehicle concept to use to explain in a simple manner the principles and methods for future commercialization.

Point

- ■ The new material "Shinayaka polymer" created by the ImPACT Ito Kohzo Program can be used for structural material and parts not just in cars, but also various types of transport equipment, and it has the potential to dramatically improve lightweightness, function, safety, and reliability characteristics of such equipment. With this project, in an attempt to verify the potential of resin material, we developed an electric vehicle (EV) concept car called "ItoP (Iron to Polymer)" using an abundance of this material to realize the effects of its application.

- ■ With “ItoP,” the resinification of the vehicle was increased to 47%, which is approximately four times that of conventional vehicles. Incorporating large side windows made of resin and integrating the clear roof and front window, we achieved a completely new form and aerodynamics with our innovative single-mold monocoque structure *1 body frame (weighing 140kg, about half the weight of conventional metal monocoques) and created a collision safety structure that is both strong and rigid.

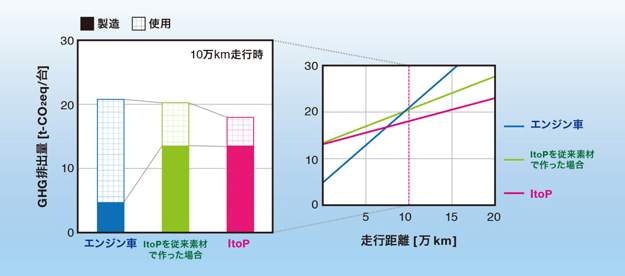

- ■ Additionally, carbon-fiber reinforced plastic (CFRP)*2 was used for parts around the wheels such as the suspension spring wheels to achieve significant weight reduction (vehicle weight of 850kg, weight reduction of 38%). The results showed that it was possible to achieve an 11% reduction in the greenhouse gas (GHG) emissions after 100,000 km, including the manufacturing process when compared to manufacture using steel, glass, and tires made from conventional materials.

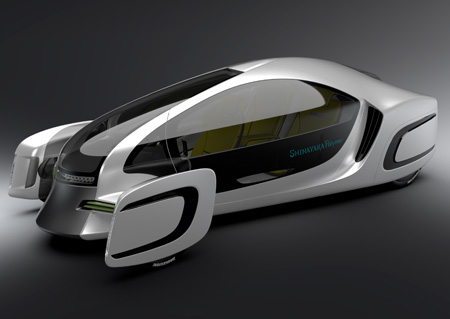

The styling design invokes an image of both flexibility and toughness, and we aimed to create a futuristic design that can only be realized because the entire vehicle is made of resin. Some major characteristics of its appearance include the integrated egg-shaped cabin and independent front wheel cover, the large windows, and the large opening doors. A similar concept was used for the interior of the vehicle with a monitoring and steering system designed with an eye towards future incorporation of self-driving functions and a 1 + 2 seat setup that seats three people. To realize this design and create a body that is lightweight and functional, we made extensive use of composites formed by strengthening resin material, including the "Shinayaka polymer" with carbon-fiber. The monocoque frame, which also functions as the body, was created using a single mold for the external skin, platform, and barrier walls to achieve high-strength, rigidity, and lightweight properties.

Additionally, we actively applied developed materials to the suspension and wheels and achieved weight reduction for all major component parts. Particularly in the front of the vehicle, we adopted a CFRP leaf spring to also act as the suspension arm to build a completely new suspension system. Combined with the CFRP coil spring adopted for the rear suspension, these parts are most representative of the parts we were able to realize by giving both flexibility and toughness to the composite material.

This material was also used in the collision safety measures of the vehicle. By applying them to the shock absorption structures located on the front, rear, and sides and the bumper beam monocoque structure doors, we were able to improve the functions. Development materials were also used in the clear windows and tires, resulting in thinner parts compared to conventional materials, and this contributed to significant weight reduction for the entire vehicle. Through the development of "ItoP," we were able to discover that the characteristics of "Shinayaka polymer" have the potential to significantly contribute to improvement in the performance and function of transport equipment such as cars. Additionally, since we can expect similar effects from the application of this material to general industrial applications and sports equipment that have similar issues and backgrounds, we expect to see the use of this material spread to areas other than automobiles and see commercial applications in the near future. This research was conducted with the cooperation of Kohzo Ito of Tokyo University, Toray Industries, Inc., Mitsubishi Chemical Holdings, Sumitomo Chemical Co., Ltd. AGC Inc., and Bridgestone Corporation.

Background and history of this research

In recent years, research and development into the substitution of materials such as metals and glass with resin have been progressing with the aim of energy savings through weight reduction of automobiles. However, even if it is possible to reduce weight, it is difficult to completely compensate for the performance and functions of metal materials, and with a simple substitute, it is difficult to fully display the features and characteristics inherent to resin materials, and this has limited the parts to which resin materials could be applied.

On the other hand, with the rapid progression of the shift towards electric and self-driving cars, we are now at a point where the structure of cars must be completely re-examined and combined with the demand for weight reduction, and it is inevitable that expectations for resinification will grow. Against this background, there are several significant obstacles that need to be overcome for resin material to take the lead role as a structural material for cars. The path to overcoming the obstacle of strength and rigidity in replacing metals can be found in methods such as fiber reinforcement, but the reduction in such characteristics like toughness, strength, resiliency, etc. have been a barrier to the application of resins.

The "Shinayaka polymer," which was developed through this program, has the characteristics to overcome these issues of conventional resins and composites. We started development with the aim to utilize these newly developed materials to produce an EV concept car that uses resin as its main structural material, realize a design and body structure that could not be made using metals and achieve significant weight reduction and energy savings through the active resinification of the component parts.

Details of the research

If we can use plastic as the main structural material of automobiles, how will cars change? How will they evolve? We approached this research by creating a basic concept. We spent more than a year creating this concept and deliberating on the styling design to consider the possibility of using plastic. As a result, we came up with a concept car with this form (Figure 1) and specs (Table 1).

(table1) Concept car main specifications

| Length×Width×Height | 4,280×1,930×1,350 (mm) |

|---|---|

| Minimum ground clearance | 140 (mm) |

| Wheelbase | 3000 (mm) |

| Front / Rear tread | 1,660 / 1,670 (mm) |

| Frontal area | 1.994 (m2) |

| Seating capacity | 3 |

| Unladen weight , Weight distribution |

850 (kg) , Front:43% Rear:57% |

| Drive format | In-wheel motor , Rear-wheel two-wheel drive |

| Rated output | 15 (kW) |

|

Rated , Maximum torque |

150, 570 (Nm) |

| Battery format | Lithium ion secondary battery |

| Rated voltage , Power capacity |

DC300 (V) |

| Rated , Maximum output | 24 , 45 (kW) |

| Charging system | Single-phase 100 / 200 (V) |

| Tire , Wheel | 155 / 70R19, 5.0J-19" |

Here we will explain the representative details of the research and development that went into each aspect of this concept car for which we attempted to increase the use of resin.

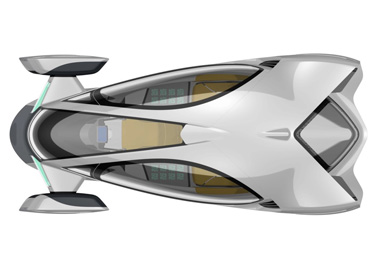

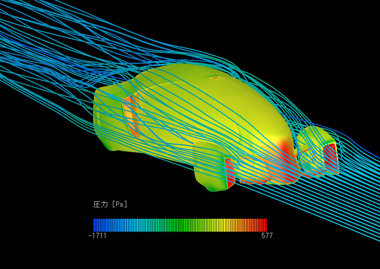

1) Styling design and aerodynamics

The external shape shown in Figure 1 and Figure 2 is a realization of our design concept of flexibility and toughness that can only be realized by making the entire body out of resin. The surface configuration of continuous curved surfaces, the large glass area and door openings, the independent front fender, and the covered rear wheels are all components of this vehicle, which has both a futuristic style and superior aerodynamic performance that contributes to energy saving.

2) Monocoque body

From the perspective of lightweightness and high-rigidity as well as high impact resistance, we adopted a monocoque structure for the body frame that also functions as the outer panel and created a single mold for the part shown in Figure 4. Combined with the superior physical properties of the composite made from carbon-fiber and thermosetting resin, this monocoque body contributed significantly to realizing our concept. In addition to increasing the degree of freedom in design, as seen with the large opening doors, it was possible to create an efficient body layout by achieving an extreme reduction in the number of parts, and this resulted in a remarkable reduction in weight. As for the weight, we achieved a reduction of more than 50% from the 300kg of the conventional metal monocoque frame to 140kg.

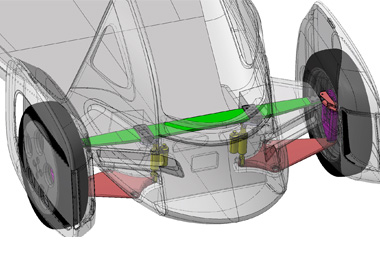

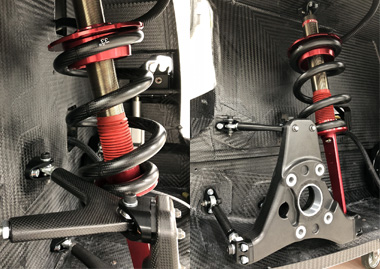

3) Suspension

It was conventionally thought that using resins for suspension parts would be difficult, but by using CFRP that adopted the slide-ring polymer*3 structure developed through this project, we were able to achieve the required performance and function, and thus resin material was adopted. We have used CFRP for all the major suspension component parts as well as the spring parts, which undergo large deformation. In the front, we used the leaf spring type (Figure 5) suspension, which is also used as the arm of the double wishbone suspension, and this contributed to the realization of the unique, independent fender and the layout is such that we can expect a vibration-damping effect of the composite material structure. With regard to the rear, we adopted a coil spring type (Figure 6) suspension and confirmed sufficient fatigue properties to withstand repetitive deformation.

4) Window material

The clear resin with both high-rigidity and high-toughness that we developed through this program was used for the windshield (Figure 7). We can expect weight reduction compared to glass parts, and the improved fracture resistance when receiving impact will be effective in improving safety against penetration by a flying object and prevention of scattering of broken pieces.

5) Tires and hubcaps

The "ItoP" was equipped with a special tire made using innovative rubber material created through this program (Figure 8). Improvement in wear resistance contributes to resource saving for the tire material, and an estimated rolling resistance of 5% and lower air resistance owing to a narrower width and larger diameter is directly linked to energy savings. CFRP incorporating the slide-ring polymer structure, as used in the suspension parts, was also used to make the hubcap. This improvement in impact resistance and the weight reduction in the rotating parts under the spring, including the tires, contributed significantly to improving the performance of the entire vehicle.

6) Crash box

Shock absorbers made using a composite of polyamide and glass fiber with a slide-ring polymer structure (Figure 9) (Figure 10) were installed on the sides and front of the “ItoP.” By using composites for the energy absorber, which is generally made of metal, weight reduction was achieved.

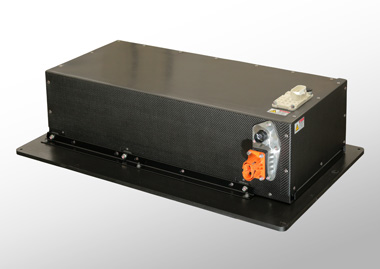

7) Battery pack

The box that contains the lithium ion secondary battery module of the EV system and the base part was made using CFRP to achieve weight reduction (approx. 30%) and improve shock resistance (Figure 11).

8) Interior

A majority of the interior panels were made using CFRP and were incorporated into the monocoque frame and part of the door structure to efficiently secure the toughness of the body, and this also contributed to weight reduction. The structural material of the seats was made using CFRP that adopted a slide-ring polymer structure, making it possible to adopt a thinner seat shell structure that is lightweight and very tough.

9) Other characteristics

The allocation of passengers with one person in the front seat and two people in the back seat, making the front seat collapsible, and the adoption of a twin-lever type steering system (Figure 13) were decisions made with an eye towards full automatic operation in the future and we focused on the comfort of the passengers seated in the back seat. We also adopted a system using smartphones and tablet computers for everything from opening and closing the doors to operating and monitoring information regarding the operation of the vehicle. The motor-assisted doors that open wide on the upper front part of the vehicle (weight 35kg per side) (Figure 14) are possible because the same material and structure as the monocoque body are used to achieve weight reduction.

10) Greenhouse gas (GHG) reduction effect

As we mentioned for each item, we have incorporated a variety of development technologies into “ItoP” in the pursuit of energy savings, including weight reduction. Professor Hirao et al. of Tokyo University conducted an inventory analysis of “ItoP” which showed a 13.7% reduction in GHG emissions after 100,000km, including the manufacturing process, when compared with vehicles with conventional engines, and a potential for 11.4% reduction when compared with "ItoP" created using conventional materials such as steel and glass (Figure 15). The factors for the reduction of GHG emissions include improvement in fuel efficiency owing to weight reduction, reduction in necessary battery capacity, and the synergistic effect of using fuel-efficient tires.

11) Use in other applications

Through the production of "ItoP,” we were able to ascertain the features and characteristics of these materials, and thus we will search for possible applications other than for automobiles. We applied the material to prosthetic blades for competition purposes to make full use of its superior toughness and fatigue resistance, and in addition to seeing an improvement in performance as expected, we were able to confirm that the material does not easily split into independent pieces when damaged (Figure 16, left), and thus less scattering of pieces can be expected when damaged.

We have also started a trial application for hockey sticks (Figure 17), which receive repetitive impact from a ball (puck). We are conducting assessments through bench tests and field tests, and we expect to see positive results.

Future developments

Through the production of "ItoP,” we believe we have been able to realize a concept for a new way of being and a new way of creating cars through the use of innovative resins. In the future, we will use these results in "monozukuri (craftsmanship)," contributing to the universal challenges of sustainability, safety, security, and low environmental load that society now demands.

― Explanation of terms ―

*1 Monocoque structure: A structure popularly used for car bodies of vehicles currently on the market.

*2 Carbon-fiber reinforced plastic (CFRP): polymer material reinforced with carbon fibers. It is lightweight but has high strength and rigidity and thus it is becoming widely used on automobiles and airplanes.。

*3 Slide-ring polymer: A molecular structure where the coupling part of the molecules can slide. Created by cross-linking the cyclic molecule in polyrotaxane with the target polymer.