Concept EV "ItoP" Suspension Made of CFRP

Confirmation of Fatigue Properties Sufficient to Withstand Repeated Deformation in Suspension Parts, Which Have Been Considered Difficult to Be Made from Resin

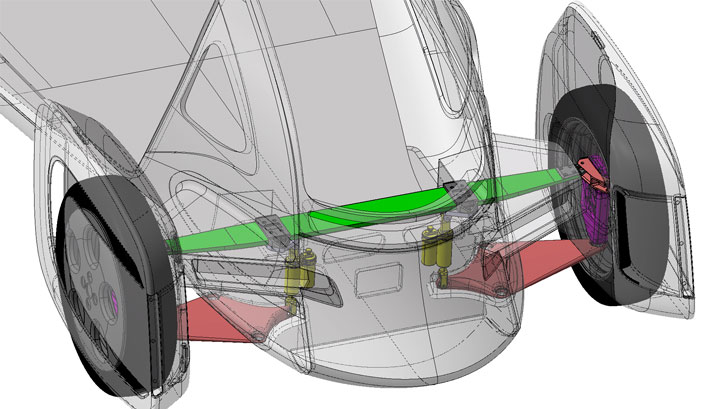

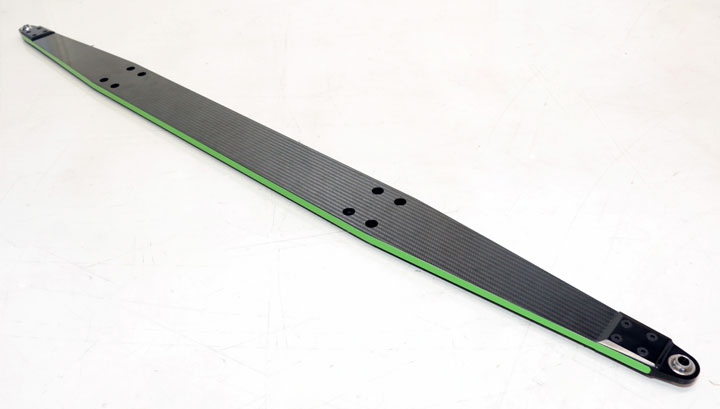

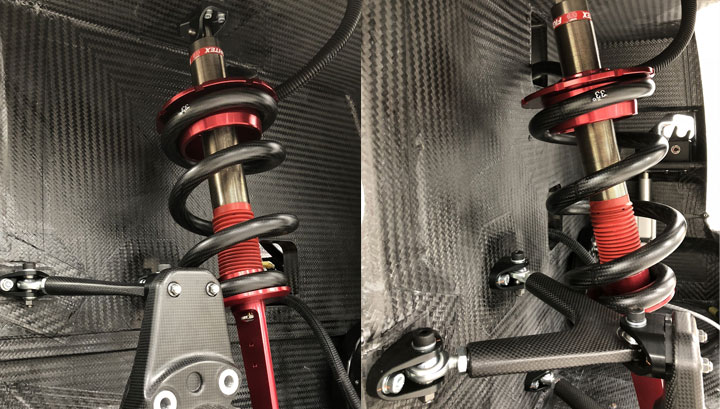

Even in suspension parts, which have traditionally been difficult to be made from resin, by using CFRP with introduction of the cyclic polymer structure developed at this time, the required performance and function has been achieved, leading to the application. Not only the main suspension components but even the spring parts that undergo large deformation have also been achieved and are made of CFRP. The front uses a leaf spring system that also functions as the arm of the double wishbone suspension, contributing to the creation of the distinctive independent fenders, and was also placed to allow for the vibration-damping properties of the composite material structure to be utilized. On the other hand, the rear used a coil spring system, and both suspensions have been confirmed to have fatigue properties sufficient to withstand repeated deformation.

| Client | Japan Science and Technology Agency (JST) |

|---|---|

| URL | https://www.jst.go.jp/impact/shinayaka/special/itop.html |

| Application | Electric Vehicle Suspension |

| Development Part | Suspension (leaf spring, spring) |

| Required Characteristics | ー |

| Development Scope | Structural Analysis / Fluid Analysis / Design / Material Selection / Evaluation Testing / Prototyping Molding Method Selection / Manufacturing / Production Technology |

| Development Period | ー |

| Molding Method | Autoclave |

| Size | ー |

| Weight | ー |