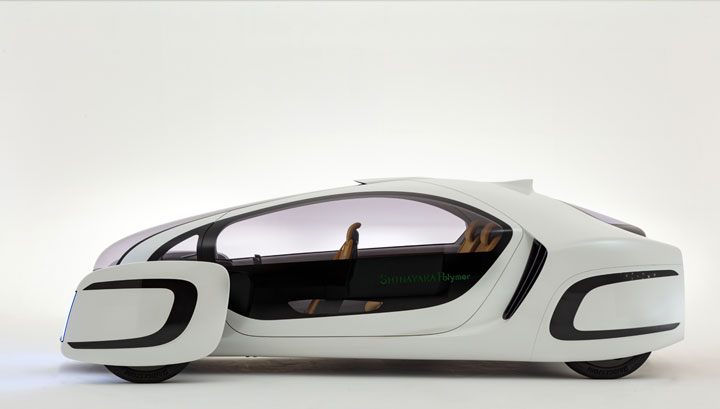

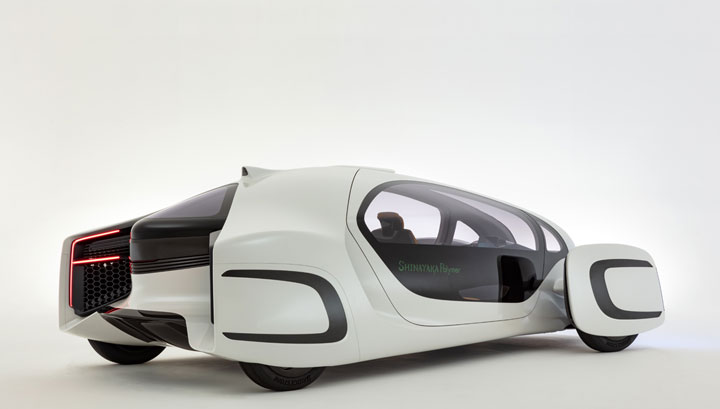

Concept EV "ItoP"

Achieving A Resinification Ratio of 47%. Development of An Innovative Concept Car with Use of The New Material "SHINAYAKA (flexible and tough) Polymers"

The styling design evokes an image of both flexibility and toughness, aiming for a futuristic design that could only be achieved in an all-resin car, with major exterior features that include a unified egg-shaped cabin, independent front wheel covers, large window areas, and wide-opening doors. The interior of the vehicle has a similar concept, with a monitoring system and steering system that anticipate future autonomous driving, and seating for three people in a 1+2 seating arrangement. To achieve this design and to construct a lightweight, highly functional vehicle body, we made extensive use of composite materials made from resin materials that include flexible and tough polymers, reinforced with carbon fiber. The monocoque frame, which also serves as the body, is molded as a single unit with bulkhead in addition to outer skin and platform, achieving high strength, rigidity, and lightweight.

| Client | Japan Science and Technology Agency (JST) |

|---|---|

| URL | https://www.jst.go.jp/impact/shinayaka/special/itop.html |

| Application | Concept EV Electric Vehicle |

| Development Part | Vehicle Design/Production |

| Required Characteristics | ー |

| Development Scope | Structural Analysis / Fluid Analysis / Design / Material Selection / Evaluation Testing / Prototyping Molding Method Selection / Manufacturing / Production Technology |

| Development Period | ー |

| Molding Method | Autoclave |

| Size | Vehicle Body Overall Length 4280 mm / Overall Width 1930 mm / Overall Height 1350 mm |

| Weight | Total Weight 850kg |