New EV Racing Concept Car "NISSAN LEAF NISMO RC"

Cooperating in Development and Manufacturing of Major Structural Components and Contributing to Lightweighting on Overall Vehicle and Optimization on Weight Balance

The new EV racing concept car NISSAN LEAF NISMO RC_02 was developed with the following concept as NISMO.

・Demonstrate the outstanding performance of Nissan Intelligent Mobility.

・Incorporate NISMO's racing technology, dynamically demonstrate the potential of Nissan EVs.

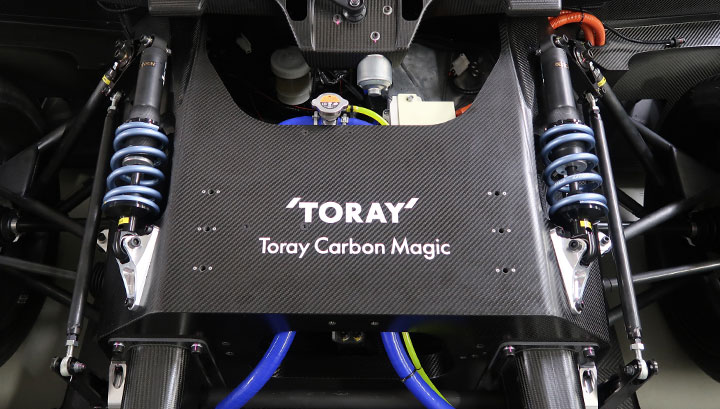

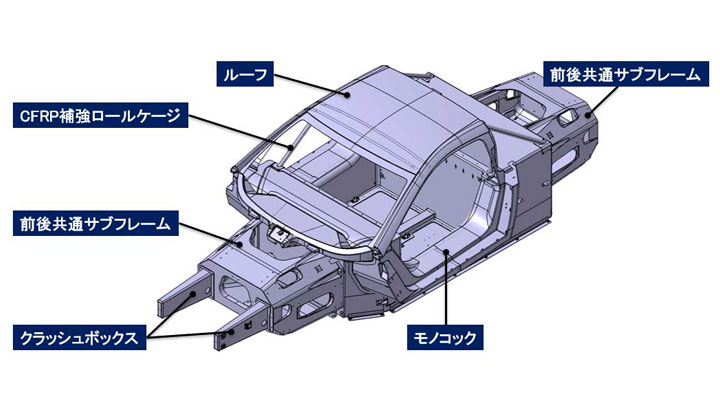

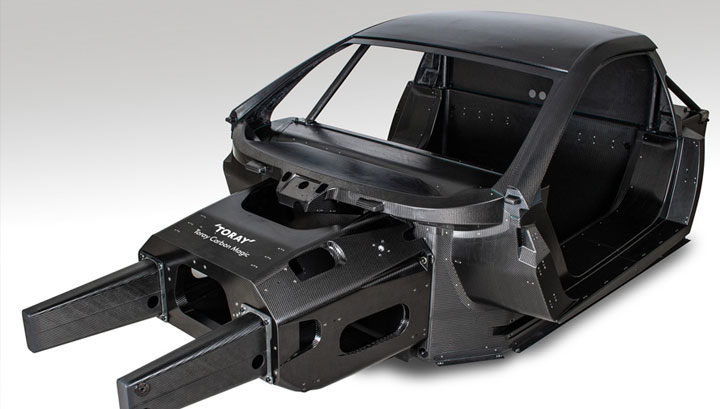

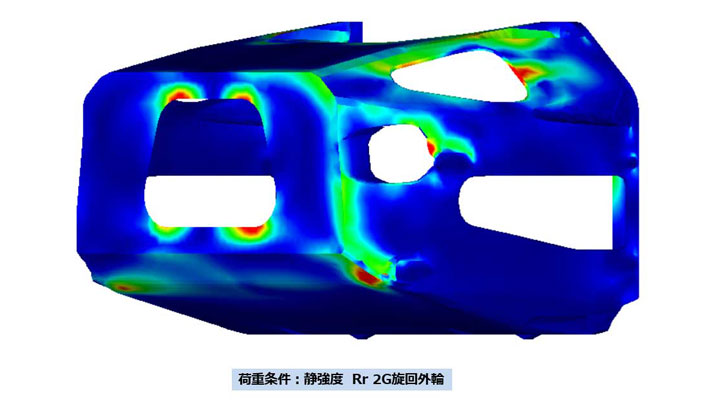

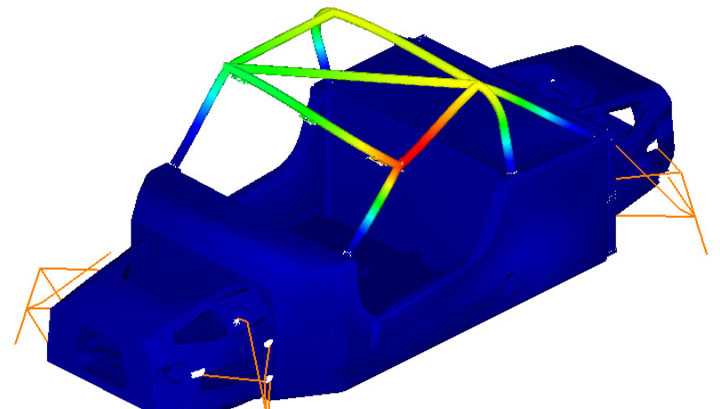

As Toray Carbon Magic, the significant lightweight has been achieved in the component development of key components such as the monocoque and subframe by cooperating in strength analysis and manufacturing process design, etc. with use of our advanced technology. Monocoque, subframe, crash box, and wing which are the main structural components, were made of CFRP with use of autoclave molding method. Lightweight has been achieved while maintaining the necessary rigidity. The roll cage of the monocoque chassis was subjected to structural analysis and reinforced with CFRP, which resulted in a smaller diameter of 38 mm and a thinner wall. It has been achieved that the subframe is approximately 25% lighter than the steel subframe of the previous model. Additionally, costs were reduced by using a common design for the front and rear. In addition, as for the roof, which is an exterior component, VaRTM was used for the molding method. The VaRTM molding method does not require prepreg materials or autoclave equipment, making it possible to reduce molding costs for planar, simple shaped parts for the roofs and bonnets.

| Client | Nissan Motorsports International Co., Ltd. |

|---|---|

| URL | https://www.nismo.co.jp |

| Application | New EV Racing Concept Car |

| Development Part | Monocoque Chassis / Common Front and Rear Subframe / Crash Box / Wing / Roof |

| Required Characteristics | Lightweight / Rigidity / Impact Energy Absorption |

| Development Scope | Structural Analysis / Design / Material Selection / Evaluation Testing / Prototyping / Molding Method Selection / Manufacturing / Production Technology |

| Development Period | Approx. 6 months |

| Molding Method | Autoclave (monocoque, common front and rear subframe, crash box, wing) / VaRTM (roof) |

| Size | Vehicle Overall Length 4546 mm / Overall Width 1942 mm / Overall Height 1212 mm |

| Weight | Total Vehicle Weight 1220kg |