Industrial Multi-Rotor "YMR-08"

By Making Aircraft Body A CFRP Monocoque (stressed-skin structure),

Integration of Many Parts Has Been Achieved, Contributing to Cost Reduction

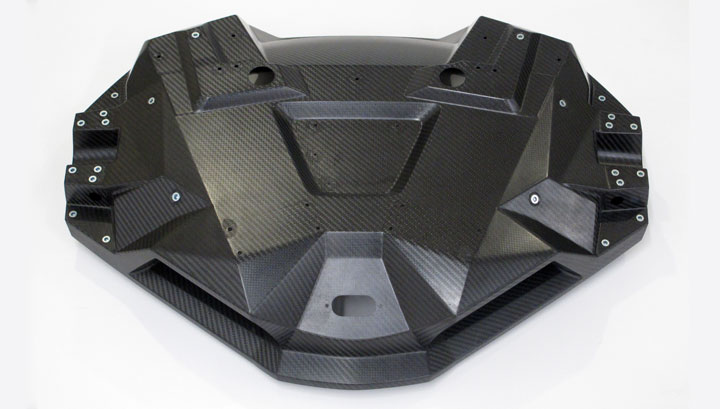

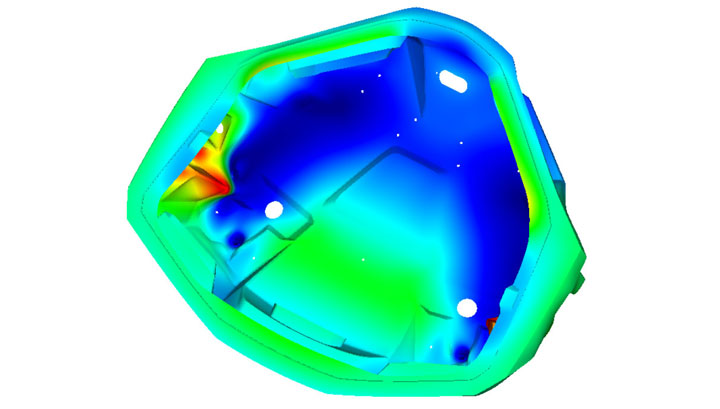

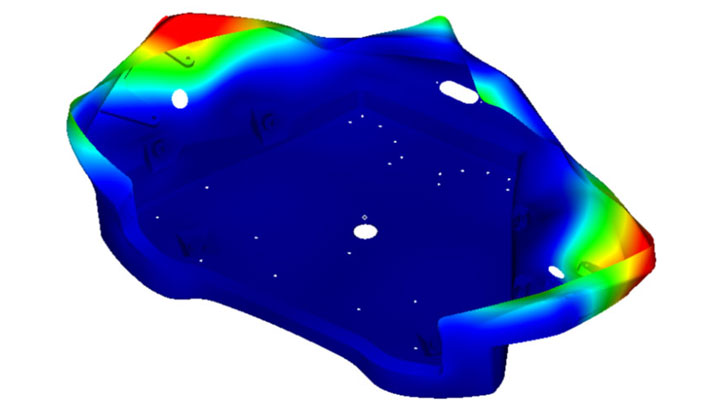

The industrial multi-rotor YMR-08 employs a CFRP monocoque body and CFRP movable propeller arms that have achieved design and ultimate lightweighting in order to achieve a maximum takeoff weight of 25 kg or less. Our company has been involved from the development stage, and has combined our unique design and analysis know-how with Yamaha's technology to complete the current part. In addition, the monocoque construction has achieved the integration of many parts, contributing to price reduction. The monocoque body is manufactured using the autoclave molding method, achieving a shape that would be difficult to mold using other methods. The propeller arm is manufactured using the sheet winding molding method. The production with use of our own materials and equipment has contributed to quality assurance and a price reduction.

| Client | Yamaha Motor Co., Ltd. |

|---|---|

| URL | https://www.yamaha-motor.co.jp/ums/multi/ |

| Application | Drone (unmanned aircraft) |

| Development Part | Monocoque Body / Propeller Arm / Boom |

| Required Characteristics | Lightweight / Rigidity / Design |

| Development Scope | Structural Analysis / Design / Material Selection / Evaluation Testing / Prototyping / Molding MethodSelection Manufacturing / Production Technology / Mass Production |

| Development Period | Approx. 3 years |

| Molding Method | Autoclave (monocoque body) / Sheet Winding (propeller arm, boom) |

| Size | Aircraft Maximum Overall Length 1923 mm / Maximum Overall Width 2181 mm / Overall Height 669 mm |

| Weight | Aircraft Maximum Takeoff Weight 24.9 kg or less |